Blog Feed

Categories:

Arrow recently wrapped up a large-scale exterior restoration for a Condominium Association in Morton Grove, Illinois, focused on restoring strength […]

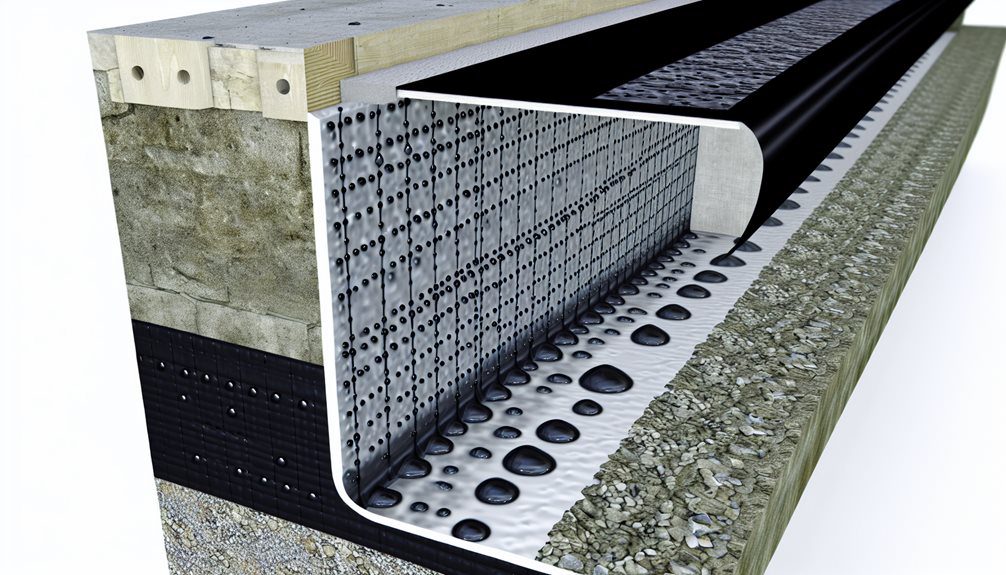

Keep your commercial basement dry and protected with proven waterproofing solutions that shield against moisture damage and extend structural life.

From eco-friendly materials to smart monitoring systems, modern masonry transforms commercial buildings while redefining architectural boundaries.

Discover essential strategies for preserving load-bearing brick walls, from critical inspection schedules to cost-effective maintenance techniques that prevent structural failure.

Innovative waterproofing solutions now integrate smart sensors and self-healing materials, revolutionizing how commercial buildings combat moisture damage.

Correct chimney function dramatically impacts HVAC efficiency, but most building owners overlook this critical connection between airflow and energy costs.

Arrow recently completed a full-spectrum exterior restoration on a mixed-use midrise building in Wood Dale, Illinois, focused on both aesthetics […]

Arrow recently completed a comprehensive masonry restoration for a Townhome Association in Arlington Heights, Illinois, enhancing both protection and appearance. […]

Just when you thought crumbling brick was destroying your retail curb appeal, these masonry restoration secrets could transform your storefront forever.