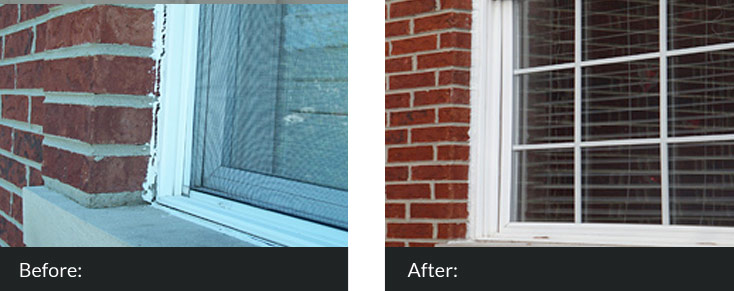

Caulking Before & After

Caulking is one of Arrow Masonry’s value added services as it uses the rigging already in place for our core tuckpointing and masonry restoration procedures. It is also another preventative maintenance device for thwarting leaks. An open caulk joint can cause the same amount of damage as a void within a mortar joint can, by allowing unwelcome water into your buildings.

Arrow Masonry implements a variety of sealant products depending on job specifications. Polyurethane, silicone, and butyl rubber caulk are commonly used to form a watertight seal to all types of perimeter, control and expansion joints.

Caulking F.A.Q.s

How do I know if I need caulking on my building?

How should I inquire for a Caulking quote?

Reviews

“I picked your company from the phone book to get three estimates for work. I knew your estimator from previous work, and I decided then to use Arrow. The price was the best of the three and I knew that the work would be good, and it was. The house looks beautiful and the area was cleaned up superbly. The phone staff is excellent and very professional. I would highly recommend Arrow.”

“We received numerous quotes for our work and Arrow was the best combination of price, courteous service and promptness. We would definitely use you again.”

“Your men were outstanding, efficient, excellent workmanship, reliable, and they cleaned up wonderfully!! A real pleasure to work with!”

“You responded to our phone call extremely promptly (very important to us) and advised us to look at another property in order to see what the finished product would be. This made our decision to use Arrow.”

“Your estimator was why I decided on Arrow. He would quickly return my phone calls and answer questions promptly. He also assured me of satisfaction with the job, which my wife and I are. Thank you.

Leave a Review Read All Reviews

Commercial Tuckpointing, Masonry & Brick Repair in the Chicagoland Area

- Algonquin

- Alsip

- Arlington Heights

- Aurora

- Barrington

- Bartlett

- Batavia

- Bensenville

- Berwyn

- Bloomingdale

- Bolingbrook

- Buffalo Grove

- Carol Stream

- Cary

- Chicago

- Cicero

- Cook County

- Countryside

- Crystal Lake

- Deer Park

- Deerfield

- Des Plaines

- Downers Grove

- DuPage County

- Elgin

- Elk Grove Village

- Elmhurst

- Evanston

- Forest Park

- Franklin Park

- Geneva

- Gilberts

- Glen Ellyn

- Glencoe

- Glenview

- Grayslake

- Gurnee

- Harwood Heights

- Highland Park

- Hinsdale

- Hoffman Estates

- Huntley

- Inverness

- Itasca

- Kane County

- Keeneyville

- Kenilworth

- Kildeer

- La Grange

- Lake County

- Lake Forest

- Lake in the Hills

- Lake Zurich

- Libertyville

- Lincolnshire

- Lincolnwood

- Lisle

- Lombard

- Long Grove

- McHenry

- McHenry County

- Medinah

- Melrose Park

- Morton Grove

- Mt. Prospect

- Naperville

- Niles

- Norridge

- North Chicago

- Northbrook

- Northfield

- Northlake

- Oak Brook

- Oak Lawn

- Oak Park

- Orland Park

- Oswego

- Palatine

- Park Ridge

- Prospect Heights

- River Grove

- Riverside

- Rockford

- Rolling Meadows

- Roselle

- Rosemont

- Schaumburg

- Schiller Park

- Skokie

- South Barrington

- St. Charles

- Streamwood

- Tinley Park

- Vernon Hills

- Villa Park

- Wauconda

- Waukegan

- West Dundee

- Wheaton

- Wheeling

- Will County

- Wilmette

- Winnetka

- Wood Dale

- Woodstock