Professional Lintel Replacement Services

"Lintels (angle irons), I-Beams and C-Channels with welded plates are all used to bridge openings within masonry walls."

Chicagoland Tuckpointing And Masonry Repair

Servicing all your masonry restoration needs while preserving your building's cosmetic appeal...

Our Services Include:

Tuckpointing

Masonry Restoration

Brick Repair

Stone Restoration

Lintel Replacement

Panel Brick Repair

Chimney Repair

Caulking

Waterproofing

Power Washing

Expert Repair of Failed Steel and Stone Lintels

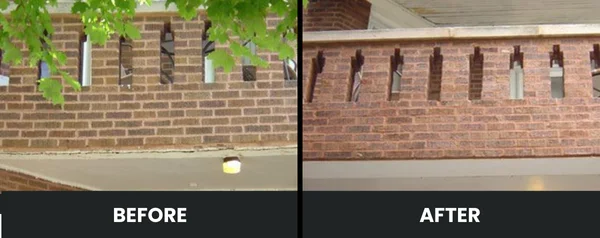

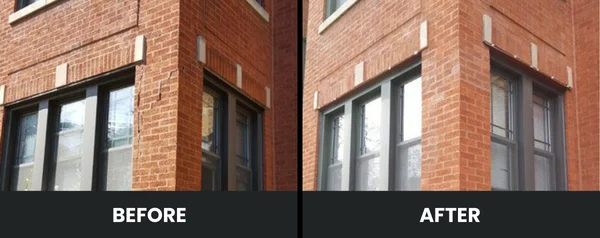

Lintel replacement fixes the structural supports above windows and doors that crack, rust, or fail over time. When lintels fail, you see cracks in mortar, displaced bricks, and water damage. Left unaddressed, failed lintels can cause significant structural damage and expensive repairs.

If you're seeing cracks above windows or doors, rust stains on brick, or sagging masonry, you likely have lintel problems that need professional attention.

What Are Lintels?

Lintels are structural supports that span the opening above windows and doors. They carry the weight of the masonry above, transferring it to the solid wall on each side of the opening.

Types of Lintels:

Steel Lintels (Most Common):

- Angle iron (L-shaped steel)

- Used in most Chicago buildings from 1900s-present

- Rust over time, especially when exposed to moisture

- Expand when corroded, cracking surrounding masonry

Stone Lintels:

- Limestone, sandstone, or granite

- Common in older buildings

- Can crack from stress or age

- Sometimes need stone restoration or replacement

Concrete Lintels:

- Precast or poured in place

- Found in some buildings

- Can crack or break down

- Less common than steel

Without proper lintels, masonry above openings collapses. That's why failed lintels are serious structural issues.

Signs of Lintel Failure

Cracks Above Windows and Doors

Stair-step cracks: Follow mortar joints in a diagonal pattern from the corners of openings.

Horizontal cracks: Run along where the lintel sits behind the brick face.

Vertical cracks: Appear when unsupported masonry is settling.

These cracks mean the lintel isn't carrying the load properly.

Rust Stains

Orange or brown staining on brick faces indicates:

- Steel lintel is rusting

- Rust is bleeding through brick or mortar

- Expansion is cracking surrounding masonry

- Problem is progressing

Displaced or Loose Bricks

When lintels rust and expand:

- Bricks above get pushed out

- Mortar cracks completely

- Bricks become loose or unstable

- Individual bricks may fall

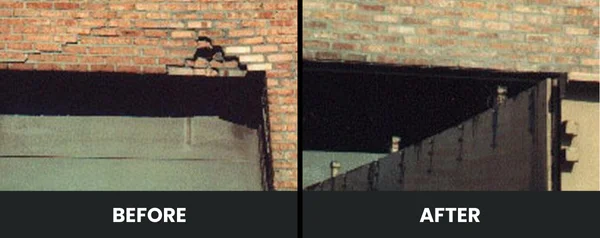

Sagging Masonry

Visible sag above openings means:

- Lintel has failed completely

- Masonry is unsupported

- Serious structural problem

- Immediate attention needed

Water Leaks

Failed lintels often cause:

- Cracks that let water in

- Interior water stains above windows

- Rot in window frames

- Mold around openings

Don't ignore these signs. Failed lintels get worse quickly and can cause serious structural damage.

Why Lintels Fail

Corrosion (Steel Lintels)

Steel rusts when exposed to moisture from:

- Failed tuckpointing letting water behind brick

- Caulking failure around windows

- Roof or gutter leaks

- Condensation

- No protection on lintel ends

When steel rusts, it expands up to 10 times its original volume. This expansion cracks everything around it.

Poor Original Installation

Common problems:

- Lintel too short (doesn't extend far enough into wall)

- No bearing surface or support

- Undersized for the load

- No protection against moisture

Age

Even properly installed lintels deteriorate:

- Steel lintels from early 1900s are over 100 years old

- Corrosion happens gradually over decades

- Eventually all unprotected steel corrodes

Water Infiltration

Water is the enemy:

- Gets through failed mortar joints

- Penetrates around windows

- Comes from roof or chimney problems

- Accelerates corrosion dramatically

Our Lintel Replacement Process

1. Assessment

We inspect to determine:

- Which lintels have failed

- Extent of damage to surrounding masonry

- Whether temporary support is needed

- Size and type of replacement required

- Related issues needing attention

2. Structural Support

Before removing failed lintels:

- We install temporary support structure

- This holds the masonry above safely

- Prevents collapse during replacement

- Allows safe work on the lintel

Never attempt lintel replacement without proper structural support. This is dangerous.

3. Masonry Removal

We carefully remove:

- Bricks immediately above the lintel

- Enough to access the full lintel

- Old failed lintel

- Any deteriorated surrounding material

Work is done carefully to minimize damage to sound masonry.

4. Lintel Installation

New steel lintels are properly installed:

- Sized correctly for the span and load

- Extended minimum 8 inches into solid wall each side

- Set on solid bearing surface

- Protected against future corrosion

- Level and properly positioned

We use heavy-duty galvanized or stainless steel for long life.

5. Masonry Restoration

After lintel installation:

- Bricks are replaced

- Proper mortar is used

- Tuckpointing matches existing

- Work is cleaned and finished

- Everything cures properly

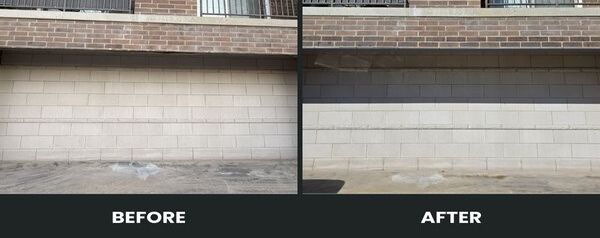

6. Waterproofing and Sealing

To prevent future problems:

- Caulk around windows properly

- Address any drainage issues

- Apply waterproofing if appropriate

- Ensure proper mortar joints

Stone Lintel Restoration

Stone lintels require different approaches:

When Stone Lintels Can Be Repaired:

- Minor cracks

- Surface damage only

- Structural capacity still adequate

- Historic preservation requirements

Methods include:

- Pinning cracks with stainless steel

- Consolidation treatments

- Dutchman repairs for missing sections

When Stone Lintels Need Replacement:

- Cracked completely through

- Severely deteriorated

- Inadequate for current loads

- Safety concerns

Replacement options:

- New stone cut to match original

- Salvaged stone from architectural salvage

- Steel lintel faced with stone for appearance

Stone work requires specialized expertise.

Prevention and Maintenance

Prevent Lintel Corrosion:

Keep water out:

- Maintain tuckpointing

- Keep caulking around windows fresh

- Fix roof and gutter problems

- Address drainage issues

Regular inspections:

- Check for cracks annually

- Look for rust stains

- Monitor any problems

- Address issues early

Protective measures:

- Waterproof when appropriate

- Ensure proper flashing

- Maintain window seals

When to Replace Lintels:

Don't wait for failure. Replace when you see:

- Cracks forming above openings

- Rust stains appearing

- Bricks starting to displace

- Any evidence of corrosion

Early replacement costs less than emergency repairs after collapse.

Related Services

Lintel replacement usually involves:

- Brick Repair - Replacing damaged bricks around lintels

- Tuckpointing - Repointing all joints in the repair area

- Caulking - Sealing around windows after repair

- Waterproofing - Preventing future water infiltration

- Stone Restoration - For stone lintel work

- Masonry Restoration - Complete building restoration

We coordinate all this work together efficiently.

Common Questions

How do I know if my lintels need replacement? Look for cracks above windows and doors, rust stains, displaced bricks, or sagging masonry. Get a professional inspection if you see any of these.

Can you just repair the cracks? No. Cracks are symptoms of failed lintels. Tuckpointing the cracks without replacing the lintel just covers up the problem temporarily. It will fail again.

How long do new lintels last? Properly installed galvanized or stainless steel lintels with good water protection last 50-100+ years.

Do all the lintels need replacement? Not necessarily. We inspect each opening and replace only failed or failing lintels. Sound lintels are left alone.

Can lintel work be done in winter? Yes, though mortar work requires appropriate weather. We work year-round with weather precautions when needed.

Will you match my brick? We match brick as closely as possible. Expect about 90% accuracy, with new brick blending better over time.

Is this covered by insurance? Sometimes, if failure resulted from a covered event. Usually maintenance-related lintel failure isn't covered. Check your policy.

Why Choose Arrow Masonry

Structural Expertise

Lintel replacement is structural work. We understand loads, bearing, and proper installation methods.

50+ Years of Experience

We've replaced thousands of lintels throughout Chicagoland. We know what works and what doesn't.

Proper Methods

We use temporary support, proper-sized lintels, correct installation techniques, and quality materials.

Complete Service

From inspection to final caulking, we handle every aspect of lintel replacement.

Licensed and Insured

Fully certified and insured for your protection.

See our work and read reviews.

Get Your Free Lintel Inspection

We'll assess your lintels, explain what needs replacement, and provide a detailed estimate.

Call: (847) 776-6400

Serving Chicagoland with professional lintel replacement services.

Learn more about Arrow Masonry.

Professional lintel replacement since 1972. Structural repairs done right.

Lintel Replacement F.A.Q.s

Your existing lintels should be sound, straight and level. In addition, the seam between the steel and the brick should be minimal. Large gaps between the lintel and brick are an indication that the steel is substandard. Other signs to look out for are a rolling effect of the steel plate or drooping in the middle of the angle iron. In any of these cases, lintel replacement is obligatory.

Simply complete the request for quote form below.